The Ancient Protein Clock That Ticks Without DNA

TL;DR: Peptide therapeutics are redefining drug development by bridging the gap between small molecules and biologics, offering precision targeting with better tissue penetration. Recent FDA approvals, advanced design techniques like stapling and cyclization, and a projected market growth to $81.5 billion by 2034 signal their expanding role in treating cancer, metabolic diseases, and rare conditions.

Within the next five years, your medicine cabinet will likely contain peptide drugs that didn't exist a decade ago. These molecular middleweights are transforming drug development, sitting between traditional pills and complex biologics. They're small enough to synthesize in a lab yet sophisticated enough to hit targets that have frustrated pharmaceutical scientists for generations. The revolution isn't coming; it's already reshaping how we treat diabetes, cancer, and rare diseases.

Peptide therapeutics occupy a unique space in the drug universe. They're chains of amino acids, typically 5 to 50 units long, shorter than full proteins but longer than conventional small molecules. This middle ground gives them superpowers that neither category can match.

Think of small molecule drugs as skeleton keys: compact and cell-penetrating, but often hitting multiple locks, causing side effects. Biologics like antibodies are precision instruments, highly specific but too large to enter most cells. Peptides thread the needle. They can recognize targets with antibody-like precision while being small enough to reach intracellular spaces.

Insulin proved this concept a century ago. At 51 amino acids and 5,808 Daltons, it demonstrated that peptides could be manufactured, stored as stable hexamers, then convert to active monomers in the body. That hexamer-monomer trick solved a formulation puzzle that still informs peptide design today.

But early peptides had fatal flaws. Injected into the bloodstream, they'd last minutes before enzymes shredded them. They couldn't cross cell membranes. The body's defenses, honed over millions of years to break down dietary proteins, treated therapeutic peptides as snacks.

Modern peptide design addresses those weaknesses head-on. Scientists have developed three main strategies to make peptides drug-worthy.

Stapling uses hydrocarbon bridges to lock peptides into rigid shapes. Researchers at Harvard pioneered this in 2000, using ring-closing metathesis chemistry to create all-hydrocarbon cross-links. The staple forces the peptide into an alpha-helix, the shape many proteins naturally adopt. This rigidity protects against proteases, increases target binding, and somehow enables cell penetration.

Aileron Therapeutics ran the first stapled peptide clinical trial in 2013 with ALRN-5281, a growth hormone-releasing hormone agonist. Their follow-up candidate, sulanemadlin (ALRN-6924), targeting the p53/MDM2 pathway in cancer, reached Phase 2a trials. These weren't just proof-of-concept experiments; they showed stapled peptides could survive human biology long enough to work.

Cyclization takes a different approach: connect the tail to the head, forming a molecular ring. Cyclic peptides resist digestion because proteases evolved to attack linear chains with free ends. Close the loop and the enzymes can't get a grip. Cyclosporin, the immunosuppressant that made organ transplants routine, is a cyclic peptide. So is colistin, a last-resort antibiotic.

The ring structure also reduces conformational flexibility. A linear peptide writhes through countless shapes, most of them useless for binding. A cyclic peptide has fewer options, spending more time in the active conformation.

Cell-penetrating sequences solve the membrane problem. TAT peptide, derived from HIV's transactivating transcriptor protein, was the first discovered. Rich in positively charged arginine and lysine residues, these sequences interact with negatively charged cell membranes. The exact mechanism remains debated: direct penetration through lipid bilayers, endocytosis, or transient pore formation. Probably all three, depending on peptide structure and cell type.

Recent work shows some cell-penetrating peptides exploit cancer-specific membrane compositions. Normal cells and tumor cells display different lipid profiles. pVEC, for instance, preferentially enters cancer cells, reducing toxicity to healthy tissue.

The FDA approved five peptide drugs in 2024, a signal that the field has matured beyond insulin analogs.

Palopegteriparatide (Yorvipath) treats hypoparathyroidism by mimicking parathyroid hormone with extended duration. PEGylation, attaching polyethylene glycol chains, shields the peptide from clearance, enabling once-daily dosing instead of multiple injections.

Pegulicianine (Lumisight) represents a different application entirely: an intraoperative fluorescent probe. Surgeons inject it during breast cancer lumpectomy. The peptide homes to tumor margins and fluoresces under specific light, showing surgeons in real time which tissue to remove. This isn't systemic therapy; it's precision-guided surgery at the molecular level.

These approvals span therapeutic categories: metabolic disorders, rare diseases, oncology. That diversity matters. It means peptide therapeutics aren't a one-trick pony but a platform technology applicable across medicine.

The pipeline is robust. ATX-101, targeting proliferating cell nuclear antigen (PCNA) in glioblastoma, showed antitumor efficacy alone and with radiotherapy in animal models. Phase 1 trials in humans reported safety and preliminary activity. PEP-010, disrupting caspase-9/PP2A interactions to restore apoptosis in cancer cells, entered Phase 1/2 testing for solid tumors.

Here's the uncomfortable truth: peptide synthesis doesn't scale like small molecule chemistry.

Small molecules are made in continuous reactors, churning out tons of product. Peptides are built one amino acid at a time using solid-phase synthesis. Each coupling step requires precise chemistry, deprotection, washing, and activation. For a 20-amino-acid peptide, that's 20 repetitions. Yields drop with each cycle. Longer peptides mean exponentially worse economics.

The market is demanding scale. Metabolic disease treatments, particularly GLP-1 agonists for diabetes and obesity, require gram-to-kilogram quantities. Jan Pawlas of Polypeptide noted that existing technology platforms struggle to meet expected volumes. Companies are rethinking synthesis strategies, exploring recombinant expression systems for longer peptides and continuous-flow chemistry for shorter sequences.

Sustainability adds pressure. Traditional peptide synthesis uses large volumes of organic solvents (dimethylformamide is standard but toxic). Reagents like piperidine for deprotection are hazardous. The pharmaceutical industry is moving toward green chemistry, but peptide manufacturing hasn't caught up. Cost-effective, environmentally responsible solutions are essential for the field's long-term viability.

While headlines celebrate AI drug discovery, computational peptide design has been quietly maturing for years. The challenge is combinatorial explosion. Twenty natural amino acids in a 10-residue sequence give 20^10 possible peptides: over 10 trillion. Add unnatural amino acids, cyclization, stapling, and the design space becomes unnavigable by intuition.

Machine learning models trained on peptide-protein binding data can now predict which sequences will bind a target. Tools like PEP-FOLD and Rosetta simulate peptide conformations and docking. Researchers design in silico, synthesize only the most promising candidates, then iterate based on experimental results.

One application: designing peptides that evade the immune system. Biologics often trigger antibody responses. Peptides, being shorter, present fewer epitopes but can still provoke immunity. Computational tools identify and eliminate immunogenic motifs while preserving function.

Another frontier: designing peptides that respond to disease microenvironments. Tumor tissue is acidic, hypoxic, and enriched in specific proteases. Peptides can be engineered with cleavable linkers that activate only in those conditions, sparing normal tissue.

Absorption, distribution, metabolism, excretion, and toxicity remain the primary filter where peptide drug candidates fail. These ADMET challenges are central to clinical translation.

Absorption: Oral bioavailability is peptides' Achilles heel. The acidic stomach and protease-rich intestine destroy most peptides before they reach the bloodstream. Cyclic peptides fare better; their resistance to digestion makes oral delivery feasible for some candidates. Formulation strategies (enteric coatings, permeation enhancers, nanoparticle encapsulation) are active research areas, but most peptide drugs still require injection.

Distribution: Peptides' hydrophilicity limits tissue penetration. They circulate in blood and extracellular fluid but struggle to cross lipid barriers, the blood-brain barrier most of all. Cell-penetrating sequences help, but tissue distribution remains narrower than small molecules achieve.

Metabolism: Proteolytic degradation is the central problem. Blood contains dozens of peptidases; tissues contain more. Half-lives measured in minutes are common. Stapling, cyclization, and incorporation of D-amino acids or N-methylated residues extend stability, but at the cost of increased synthesis complexity.

Excretion: Renal clearance is rapid for peptides under 5 kDa. PEGylation increases molecular weight, slowing clearance and extending half-life, but PEG itself can provoke immune responses with repeated dosing.

Toxicity: Off-target binding and aggregation are concerns. High positive charge in cell-penetrating peptides can cause hemolysis. Hydrophobic staples can drive aggregation at high concentrations. Each design modification trades one problem for another, requiring extensive optimization.

Numbers clarify where the field stands. The global peptide therapeutics market was valued at $35.8 billion in 2023 and is projected to reach $81.5 billion by 2034, a compound annual growth rate around 7.8%. That growth outpaces pharmaceuticals overall, signaling investor confidence.

Metabolic disease dominates by indication, driven by GLP-1 receptor agonists like semaglutide (Ozempic, Wegovy) and tirzepatide (Mounjaro). These peptides mimic incretin hormones, stimulating insulin secretion, slowing gastric emptying, and reducing appetite. Their success in diabetes and obesity expanded the market faster than any analyst predicted.

Oncology is the second-largest segment and the fastest-growing. Cancer's complexity demands precision targeting. Peptides can deliver cytotoxic payloads to tumor cells, modulate immune checkpoints, and disrupt intracellular protein interactions that small molecules can't reach. The pipeline has hundreds of candidates targeting different pathways, reflecting oncology's heterogeneity.

Regionally, North America leads in market share due to high R&D spending, established biotech infrastructure, and favorable reimbursement. Europe follows, with strong academic research feeding clinical pipelines. Asia-Pacific is growing fastest as manufacturing capacity expands in China and India and regional diseases drive localized development.

Investment is flowing in. Venture capital sees peptides as a sweet spot: lower development risk than biologics, higher specificity than small molecules, and addressing unmet needs. Contract development and manufacturing organizations (CDMOs) specializing in peptides are expanding capacity, betting on sustained demand.

Oncology is pushing peptide therapeutics toward personalization. Each tumor has unique mutations. Neoantigens, proteins expressed only by cancer cells due to those mutations, offer patient-specific targets. Peptide vaccines can train the immune system to recognize neoantigens, turning the body's defenses against the tumor.

The workflow sounds like science fiction but is moving into clinics. Sequence the tumor, identify mutations, predict which neoantigens will bind the patient's HLA molecules, synthesize corresponding peptide vaccines, and inject them to prime cytotoxic T cells. Early trials show promise in melanoma, glioblastoma, and lung cancer.

Manufacturing is the bottleneck. Each patient needs a custom product, synthesized on demand. Solid-phase peptide synthesizers can produce clinical-grade material in days, but current GMP facilities aren't set up for lot sizes of one. Distributed manufacturing, modular synthesis platforms, and streamlined regulatory pathways are necessary to make personalized peptides routine.

Peptides sit between small molecules and biologics in regulatory treatment. The FDA and EMA classify them as drugs if chemically synthesized or biologics if produced by recombinant expression, depending on size and complexity.

That ambiguity creates challenges. Small molecule rules focus on purity and impurity profiles; biologics rules emphasize batch consistency and immunogenicity. Peptides need both. Harmonizing requirements across regions and classes is an ongoing conversation between industry and regulators.

Accelerated approval pathways help. Orphan drug designation, for rare diseases affecting fewer than 200,000 Americans, grants faster review, tax credits, and market exclusivity. Many peptide candidates target rare metabolic disorders or cancers with few treatment options, making them eligible. Levacetylleucine (Aqneursa) for Niemann-Pick disease type C is one such example.

Combination therapies are another evolving area. Peptides used with chemotherapy, radiotherapy, or checkpoint inhibitors require interaction studies and endpoint definitions that regulators are still refining. Clinical trial design for combinations is more complex, but the potential for synergy drives companies forward.

Peptide therapeutics represent more than incremental improvement; they're expanding what drugs can do. They validate targets that were "undruggable," like intracellular protein-protein interactions. They enable diagnostics as well as therapeutics, as fluorescent probes demonstrate. They bridge chemistry and biology in a way that single-modality platforms can't.

This isn't to say peptides will replace pills or antibodies. Each class has strengths. Aspirin works because it's small, stable, and orally bioavailable. Pembrolizumab (Keytruda) works because it's large enough to selectively block PD-1. Peptides fill the gaps, and those gaps are larger than anyone expected a decade ago.

The field's maturation shows in diversification. Early peptides were hormone mimics or receptor agonists. Now they're enzyme inhibitors, immune modulators, diagnostic probes, and vaccine components. As design tools improve and manufacturing scales, applications will multiply.

Several trends will define the next decade.

Oral delivery remains the prize. If a peptide can survive the gut and reach systemic circulation, it competes directly with small molecules on patient convenience. Advances in formulation, permeation enhancers, and transporter-mediated uptake are inching closer. One approved oral peptide drug (desmopressin, treating diabetes insipidus, already exists) proves the concept; more are in trials.

Multifunctional peptides combining targeting, cell penetration, and therapeutic cargo in one molecule. Why inject a cell-penetrating peptide linked to a drug when you can design the peptide itself to disrupt the target? ATX-101 and PEP-010 illustrate this approach.

Biologics-peptide hybrids like antibody-peptide conjugates. Antibodies provide specificity and long half-life; peptides provide the warhead or immune modulation. This leverages both platforms' strengths.

Green synthesis will become non-negotiable as environmental regulations tighten. Enzymatic peptide synthesis, using proteases in reverse, could reduce solvent use. Flow chemistry offers continuous production with lower waste.

AI-driven design will accelerate from predictive to generative. Rather than screening libraries, algorithms will propose novel sequences optimized for multiple properties: binding, stability, cell penetration, and manufacturability. The first peptides designed entirely by AI are in preclinical testing.

Behind the chemistry and clinical data are patients whose lives depend on these advances. Insulin transformed type 1 diabetes from a death sentence into a manageable condition. GLP-1 agonists are giving millions of people control over obesity that diet alone couldn't achieve. Cancer peptides offer hope for tumors resistant to everything else.

Accessibility matters. Peptides are expensive to make. If manufacturing doesn't scale and costs don't drop, these drugs will remain out of reach for most of the world. Equity in medicine means not just inventing breakthroughs but distributing them.

The pharmaceutical industry is profit-driven, which drives innovation but also creates disparities. Rare disease drugs get developed because orphan incentives make them profitable. Common diseases in low-income countries often don't. How peptide therapeutics navigate that tension will shape their impact.

We're watching drug design become more precise, more personalized, and more capable. Peptides are central to that evolution, molecular tools engineered to do what nature couldn't and chemistry struggles with. The next time you hear about a breakthrough therapy, chances are it's a peptide, sitting quietly in that sweet spot between small and large, solving problems we didn't know how to approach a decade ago. That's not hype; it's the redefinition of what medicine can be.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

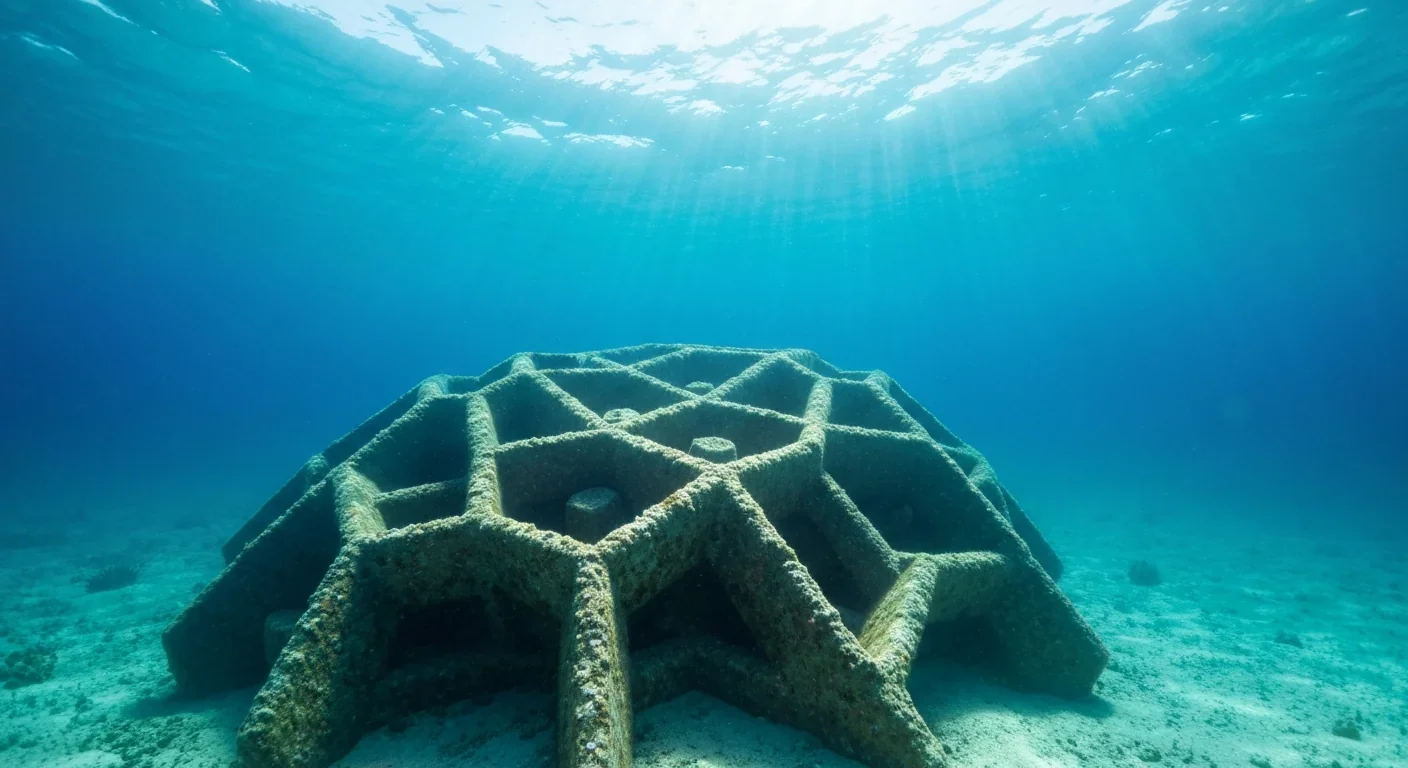

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

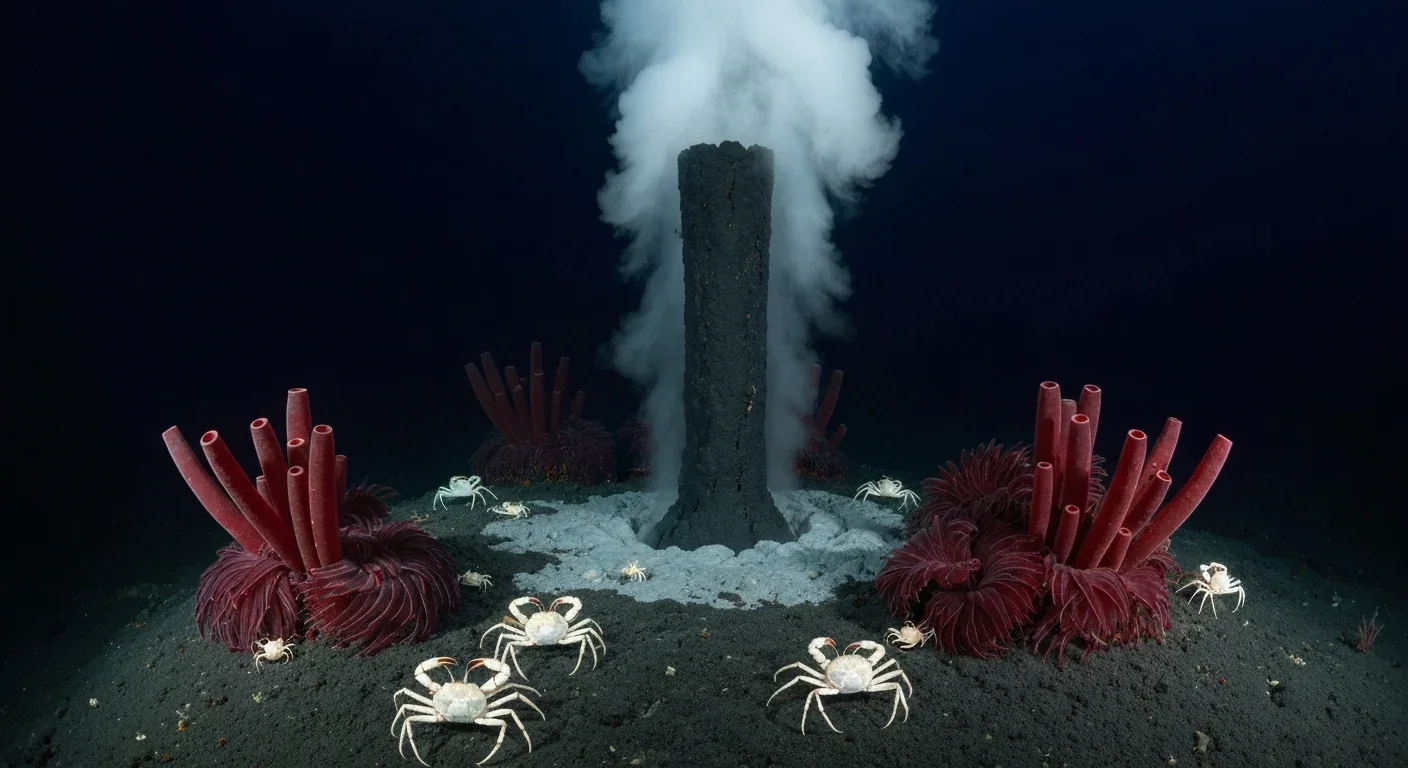

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

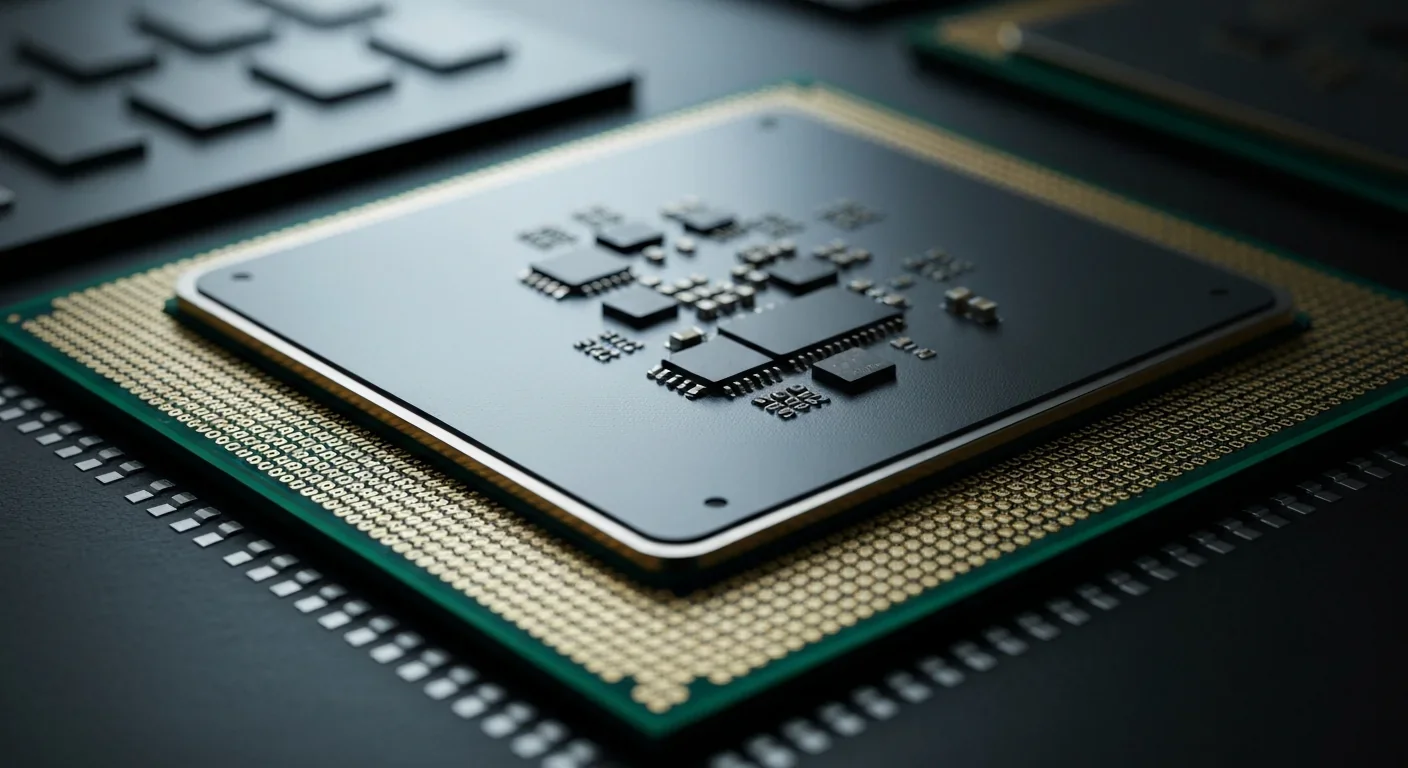

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.